Pool Table Pocket Restoration Service

If your table has top-mounted pocket irons like the one pictured, we can replace the pocket leathers and nets on your existing pocket irons.

We offer black, medium brown, or dark brown pocket colors.

In most cases, after receiving your pocket irons, we can replace the leather pocket components and ship them out within seven days.

Cost to replace pocket leathers & nets: $325.00 plus shipping

Call (410) 256-8388 or email to discuss having your leather pool table pockets restored.

Your Cart is Currently Empty

Feature Comparision of Simonis 860 vs. 860HR vs. 760 Billiard Cloth

- 90% wool / 10% nylon

- 23 oz

- Slightly slower than 760

- Nap-free

- Designed for 9-ball

- 27 colors

- 70% wool / 30% nylon

- 24 oz

- Speed between 760 and 860

- Nap-free

- Commercial or home

- 4 colors

Simonis 860™

Simonis 860™ was developed especially for 9 ball, has proven well suited for home use, and is the most popular color selection. It is also excellent for ball action and traditional 8 ball. This is a 90% wool, 10% nylon blend.

While the speed is slightly slower than 760, Simonis 860™ cloth has proven to combat ball burns better than 760 over time due to its high wool content. The combed worsted wool and high thread count assure long-lasting wear.

It is suggested to pair your Simonis cloth with a set of Aramith Belgian phenolic pool balls, which in conjunction with keeping them clean, will cut back on friction burns to the cloth surface. Aramith balls are pure phenolic and have the hardest composition and heat resistance compared to others with a lower percentage of phenolic or polyester (non-phenolic balls that will degrade quickly over time).

Residue on balls can create friction that can burn or mark the surface of the cloth. While Aramith phenolic balls can burn the felt surface, polyester balls leave some polyester behind. Keep your Aramith balls clean – to protect the cloth and achieve the best performance and appearance over time.

Simonis 860HR™

Simonis 860HR™ (High Resistant) has a speed between 760 and 860 blends (2nd fastest Simonis pool cloth-slightly ahead of Simonis 860), is a 70% wool and 30% nylon content (same as the 760 blend) but heavier than the 760 for increased durability.

While the speed is slightly slower than 760, Simonis 860 cloth has proven to combat ball burns better than 760 over time due to its high wool content. The combed worsted wool and high thread count assure long-lasting wear.

860HR has the same thread count as 860, with the shaving process changed slightly to leave a surface that is more or less a 100 % wool surface on the cloth, which is why the cloth doesn’t show marks/ball burns as much as 760 might.

Because of the weight, blend, and finishing of this cloth, the outcome gives the cloth commercial-grade durability and professional quality performance and accuracy while resisting the abuse of a high-use environment.

Simonis 860HR™ cloth is recommended for commercial and home use.

It is suggested to pair your Simonis cloth with a set of Aramith Belgian phenolic pool balls, which in conjunction with keeping them clean, will cut back on friction burns to the cloth surface. Aramith balls are pure phenolic and have the hardest composition and heat resistance compared to other balls with a lower percentage of phenolic or polyester (non-phenolic balls that will degrade quickly over time).

Residue on balls can create friction that can burn or mark the surface of the cloth. While Aramith phenolic balls can burn the felt surface, polyester balls leave some polyester behind. Keep your Aramith balls clean – to protect the cloth and achieve the best performance and appearance over time.

Simonis 760™

Simonis 760™ is the fastest Simonis cloth for pool tables and can also be found on snooker tables when the players want to play "golf" and when a color other than English green or yellow-green is desired.

It is a 70% wool / 30% nylon blend sometimes used for competitive pool tournament Play. This felt maintains its speed and accuracy and does not change the ball roll as it ages. The higher speed is great for Bank Pool, Straight pool, one pocket, and traditional 8- and 9-ball play.

Simonis 760™ is slightly faster than Simonis 860™, although the higher wool content of 860 will combat ball burns better over time.

It is suggested to pair your Simonis cloth with a set of Aramith Belgian phenolic pool balls, which in conjunction with keeping them clean, will cut back on friction burns to the cloth surface. Aramith balls are pure phenolic and have the hardest composition and heat resistance compared to others, with a lower percentage of phenolic or polyester (non-phenolic balls that will degrade quickly over time).

Also available: Simonis 760™ Outdoor Worsted Cloth is treated with a UV-resistant coating, making it perfectly suited for all types of weather.

Residue on balls can create friction that can burn or mark the surface of the cloth. While Aramith phenolic balls can burn the felt surface, polyester balls leave some polyester behind. Keep your Aramith balls clean – to protect the cloth and achieve the best performance and appearance over time.

The combed worsted wool and high thread count assure long-lasting wear.

How to Determine the Correct Rail Cushion Profile for Your Pool Table

Only one profile of cushion will give the correct nose height on a table. By installing the wrong profile, cushions will give an incorrect nose height/contact point and will impact the playability of your table.

- First, determine that your nose height (contact point of cushion rubber where the ball would hit) is 1 3/8” – 1 7/16” above the table surface (if you have a standard pool table that uses 2 ¼” balls).

- If your cushion height falls within that range, then you need to replace cushions with the same profile.

- Expose the cushion by cutting the rail cloth to expose the top side of cushion. Or remove rail cloth to expose cushion.

K66 Profile – Common for Non-Brunswick Tables

Most non-Brunswick tables will take a K66 profile that measures 1 1/8” across the top of the cushion and 1 3/16” high at the back (glue) side.

K55 Profile

K55 cushions measure 1 ¼” across the top and 1 5/16” high at the back (glue) side. Keep in mind if you have an older Brunswick (prior to 1975), be sure to measure the back side of the cushion at the glue side and confirm 1 5/16” before ordering. Older K55 cushions had a 1 5/16” back side dimension but a 1 1/8” top side measurement (same as K66).

Note: If your Brunswick table has either the older (smaller) K55 cushions or the newer K55 cushions, in virtually ALL cases, you do not need to do sub-rail modifications. There is a lot of incorrect information regarding this on forums, blogs, etc. The truth is the older K55 (smaller) and newer K55 profile cushions have the same nose height when installed. The only difference is your playfield size would be decreased by 1/4" by switching from the older (smaller) K55 to the new current version.

Brunswick 7 ft. & 8 ft. Table Profiles

If your table is an older 7- or 8-foot Brunswick table and it has the Brunswick Centennial or Contender cushions (nontriangular cushions, shaped like a “number 7”), then you need to order Brunswick Contender cushions. We also sell our Classic Billiards U56 profile cushion as a great affordable alternative.

Confused About What to Order?

If you are not getting an existing nose height for your old cushion in the range listed above, then call us at (410) 256-8388 and we will help you determine correct profile needed.

Also if you are getting a cushion dimension different than the K66, K55, and U56 profiles listed above with your contact point being correct at 1 3/8”- 1 7/16” above playfield, then you may have a smaller or uncommon profile. Feel free to call (410) 256-8388 and we can try to match up to a correct, current cushion profile.

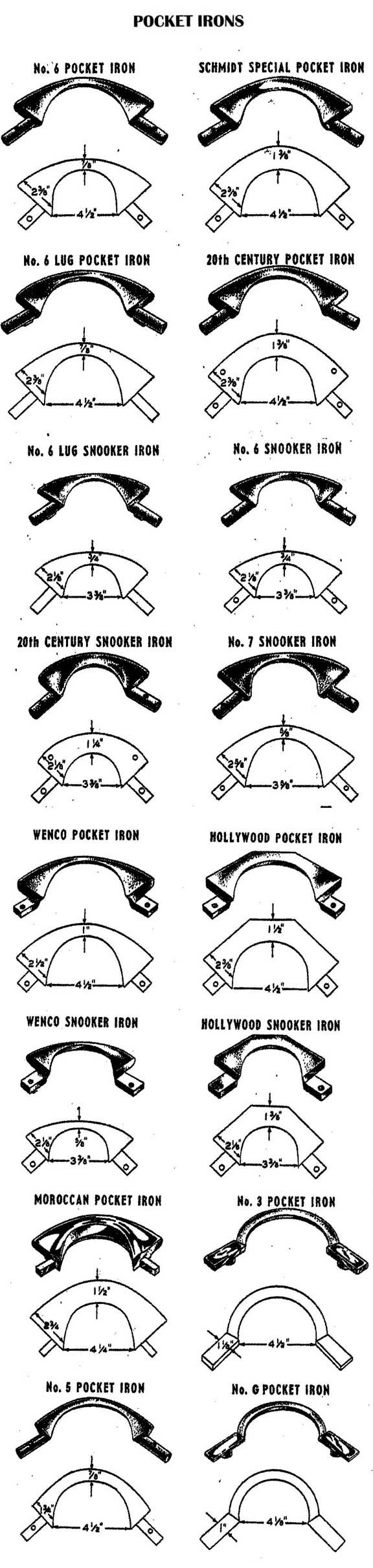

Pocket Iron Identification Chart

These photos used by permission of The A.E. Schmidt Billiard Company.

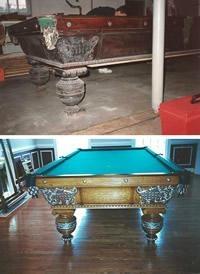

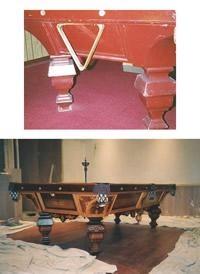

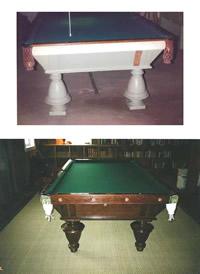

Restored Antique Billiard Tables: Before & After Photos

Below are "before & after" pictures of work we have performed in the restorations of antique pool tables.

For 20+ years, the "Classic Billiards Restoration Team" has consisted primarily of Ken Hash (owner), Paul Navarria, and Bob Standiford. We've maintained our high standards by not sub-contracting beyond this team in the restoration process.

Paul Navarria (pdnfurniturerepair.com) performs wood repairs, veneer work, inlays, and any other pre-finishing repair work needed. With 30+ years of fine woodworking skills, Paul’s expertise in the repair of antique furniture and handcrafting museum-quality reproductions has been key to our 24 years of success in the antique pool table restoration business.

Bob Standiford is responsible for the high-quality finishing work that we provide on our restorations. Bobby, with 30+ yearsof experience in furniture refinishing and touch-up service, has been part of the Classic Billiards Restoration team for over 20 years.